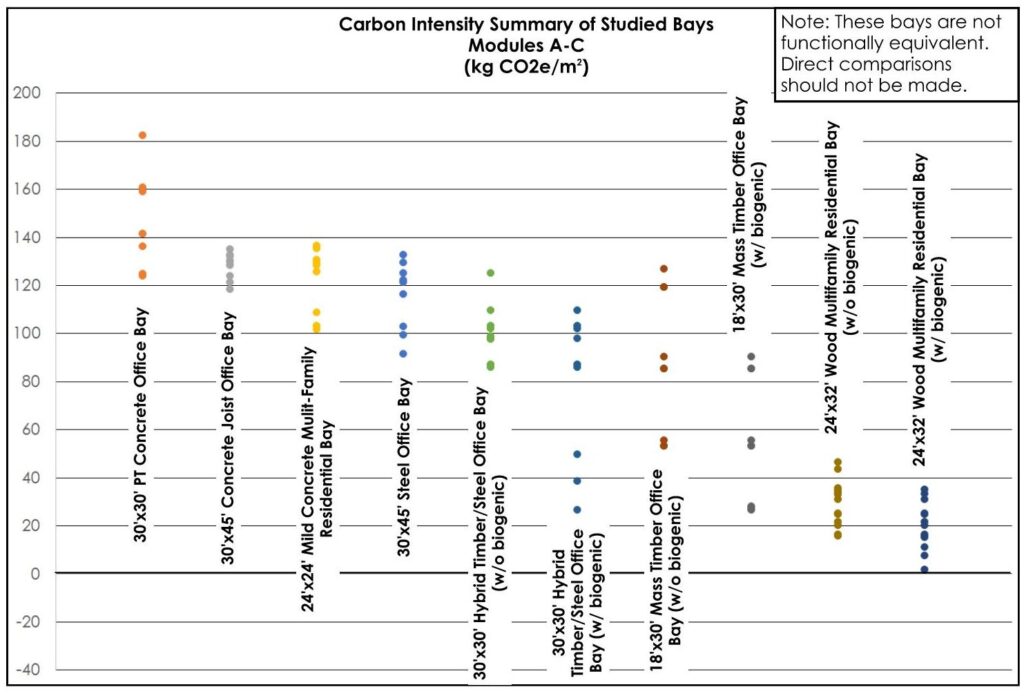

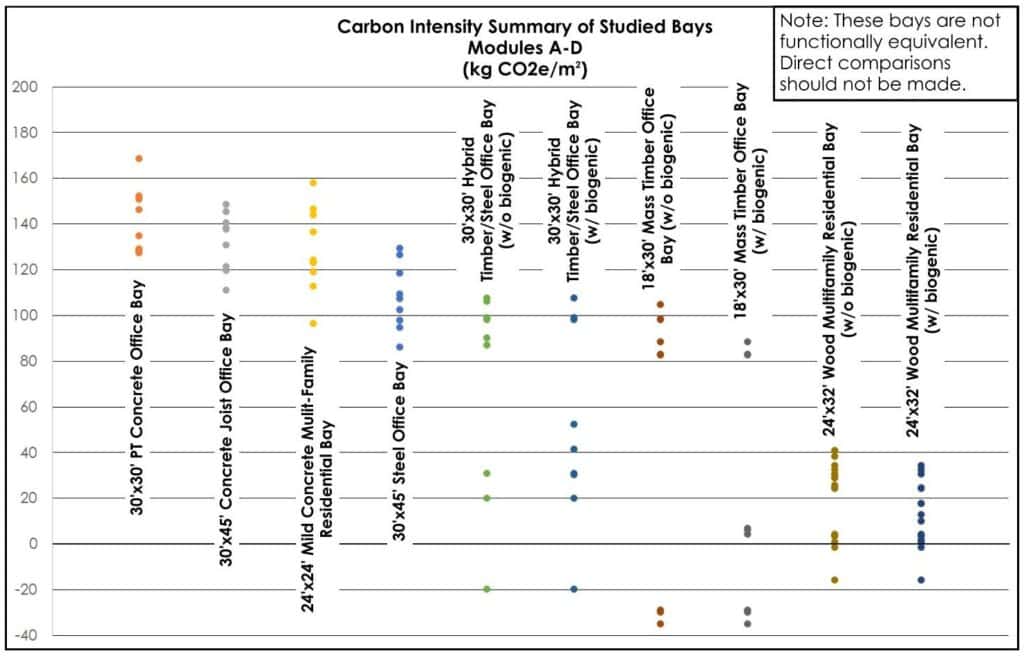

Included on this page are links to Embodied Carbon Intensity Diagrams (ECIDs) for some typical framing schemes for various building types.

The main intent of these diagrams is educational, and to provide a range of embodied carbon values for the analyzed bays to inform the practicing structural engineer of embodied carbon intensity for framing schemes considered typical.

These could also be used to back check your own assessments or even as a general guide for early design embodied carbon estimates.