Click on image below for a PDF version of this top ten list.

Top 10 Things Every Structural Engineer Should Know about Embodied Carbon

- Embodied carbon and acronyms such as CO2e and GWP are important terminology

Embodied carbon is the impact of all greenhouse gases emitted into the atmosphere by the production of a material, product, or system (measured in CO2-equivalent or CO2e). CO2e is a unit of measurement quantifying the global warming potential (GWP) of various greenhouse gases compared to an equivalent amount of CO2.

2. Embodied carbon is as important to address as operational carbon

Embodied carbon represents up to 11% of global greenhouse gas emissions and 5% of domestic greenhouse gas emissions. Structural engineers have direct influence over this portion of the climate change challenge. There have been significant advancements in energy codes, mechanical systems and architectural design that have led to reductions and efficiencies in operational carbon. As these operational emissions get closer to net-zero, embodied carbon will be even more critical to address and reduce.

3. It is important to think about upfront carbon and the time value of carbon when considering the impact of embodied carbon

Greenhouse gases released during the production of materials and buildings are emitted earlier than carbon released during the operations of the same project. This upfront carbon has an immediate impact on the climate and often accounts for the majority of a building’s total carbon footprint for much or most of a building’s life until the annual operational emissions accrue. There is no way to renovate or reduce these emissions once a building has been constructed.

4. It is possible to build a net-zero embodied carbon building using existing technology in combination with the purchase of carbon offsets

A net-zero embodied carbon or neutral embodied carbon building is when an assessment determines that a project has no net greenhouse gas emissions into the atmosphere from embodied carbon. This is achieved through a combination of emission reductions, the use of carbon sequestering materials (see item 8), and, if necessary, the purchase of verified carbon offsets. Building and material reuse are two effective emission reduction strategies that can set up a project for net zero. See the design and specification strategies pages for detailed emission reduction guidance.

5. A Life Cycle Assessment (LCA) is an environmental impact assessment framework that can be readily applied to building products and systems

LCA is a method of evaluating the environmental impacts, including the global warming impact, associated with a specific scope. A fully defined scope addresses both the elements and processes being considered and the life cycle stages included. The stages that may be considered when evaluating the embodied carbon of a project include the Product Stage (A1-A3), Construction Process Stage (A4-A5), the Use Stage (B1-B7), the End of Life Stage (C1-C4), and Beyond End of Life (D). International standards for LCAs include ASTM E2921, EN 15978, ISO 14040, and ISO 14044. See the ECID page for additional information.

6. Environmental Product Declarations (EPDs) are essential sources of product information

EPDs are reports measuring the environmental impacts of a product or material from an LCA. The typical life cycle stages measured by EPDs include the Product Stage only: Raw Materials Supply (A1), Material Transport (A2) and Manufacturing (A3), i.e. “cradle-to-gate”. Most EPDs do not include product installation, operational maintenance, or end of life considerations. The scope and reporting requirements for an EPD are governed by a Product Category Rule (PCR). The international standard for EPDs is ISO 14025.

7. A Whole Building LCA (WBLCA) is the most robust and holistic source of information for quantification of the environmental impacts of a project

A WBLCA should include as many of the building systems, scope, and life cycle stages as feasible. WBLCAs should address functional equivalency of options considered, including design loads and functionality. WBLCAs are especially useful for quantifying design strategies, such as material selection and structural configuration, in addition to procurement strategies. WBLCA results should be reported both on a whole-building basis and a per square foot basis.

8. Carbon sequestration, including the concepts of Biogenic Carbon and Concrete Carbonation, are important processes to understand in Life Cycle Assessments

Wood and other renewable materials (straw, hemp, etc.) inherently have carbon “stored” within the material through photosynthesis, which is often referred to as biogenic carbon. When these materials are used as building materials, this biogenic carbon can be stored during the building’s service life. Once a structure is demolished, a majority of the stored biogenic carbon is released back into the atmosphere through decomposition and burning. Deconstructing rather than demolishing buildings and reusing the reclaimed materials extends the carbon storage benefits. Claiming a reduction in life cycle carbon due to sequestration involves a number of variables, including forest management practices and the end-of-life fate of the material. For this reason, it is common to report LCA results with and without biogenic carbon included.

Concrete sequesters carbon over time through a process known as carbonation. It is estimated that approximately 10% of the emissions associated with the production of the cement and concrete for a structure can be sequestered over the structure’s life, with a larger degree of carbonation occurring during the end-of-life stage. The industry is working to support accurate accounting of carbon sequestration through carbonation. Consideration of this process reduces the life-cycle impact of concrete emissions.

9. Where and who your construction materials come from matters

The location of a material or product’s extraction and manufacturing can significantly influence the magnitude of its embodied carbon. Producers, manufacturers, and fabricators who source local raw material, use a larger percentage of recycled material, or obtain electricity from a renewable energy source can greatly reduce the embodied carbon of their material or product. Always try to obtain and compare EPDs from multiple manufacturers that may supply a project’s material to help inform decision-making and allow for comparison to industry averages.

10. Structural engineers play a crucial role in reducing embodied carbon

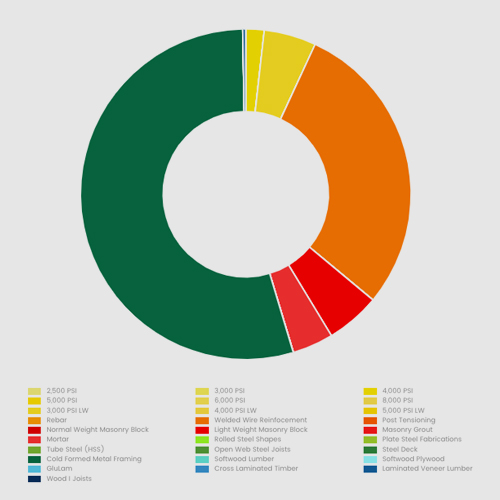

Some strategies structural engineers can use to reduce a project’s embodied carbon are using alternative materials like fly ash and slag in concrete, selecting an efficient structural system for the building type and usage, optimizing structural material usage, conducting whole building life cycle assessments to inform decision making, and increasing the service life of a building. Structural engineers should be engaged early and often in the design process to facilitate these strategies. See the Design Guidance and Specification Guidance pages for more details.